Home > Products > STUD WELDING MACHINE... > DA-1200i

CONTACT US

- Tel: 86-510-85589569

- Email: info@solidstudwelding.com

- Fax:86-510-85589565

- Address: Taihu West Rd No.2168, Binhu District, Wuxi, Jiangsu province, CHINA.

DA-1200i

- Introduction

- The models

- Advantage

- Inquire

Condition: New

Place of Origin: China (Mainland)

Brand Name:Solid stud welding machine

Model Number: DA-1200 IGBT welding machine

Arc Current: 200A-1200A

Pulse Frequency: 50/60Hz

Pilot Arc Current: 160A

Rated Duty Cycle: 15%

Dimensions: 880mmx368mmx560mm

Usage: Welding M3-M16 Studs for shipbuilding, power plant, kiln, boiler etc.

Voltage: AC 3~280V-440V

Power(W): 40KW

Certification: CE

Warranty: One years from the shipment date

After-sales Service Provided: Engineers available to service machinery overseas Weight: 90KG

Welding Range: M3mm-M16mm

Welding Time: 0.1S-3.0S

Welding Speed: M16 10PCS/minute

Power Switch: 63A

Protect Grade: Ip23

Cooling Way: F

Welding mode: drawn arc stud welding machine

Technology: IGBT inverter drawn arc

Metal welding machine:DA-1200 IGBT Solid stud welding machine

|

DA-1200i Solid stud welding machine 1. Technical Parameters

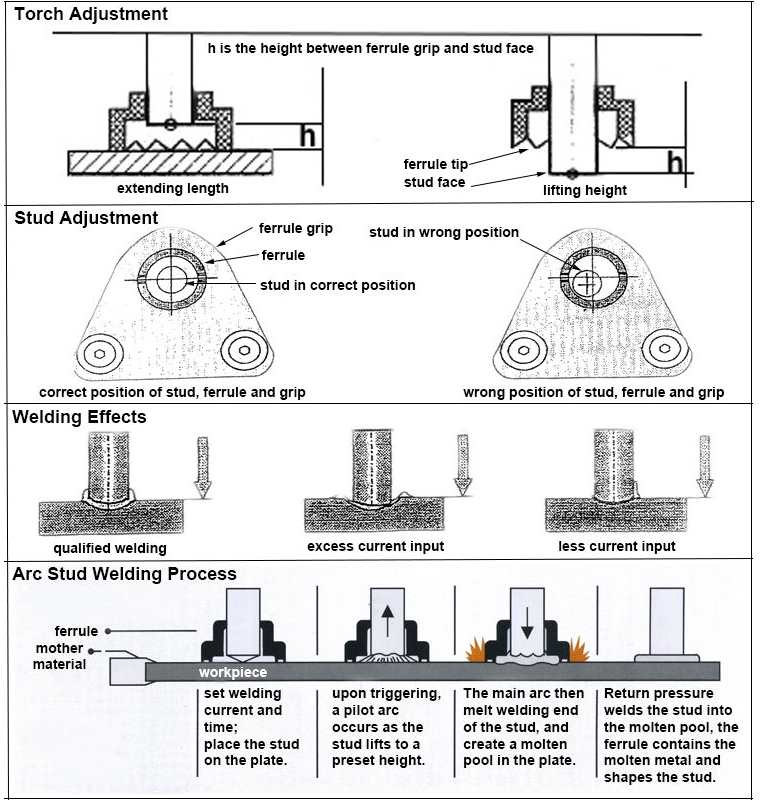

2. Welding machines features (1) IGBT Inverter technology. (2) Low price, less weight, power efficient, safe and reliable. (3) Easy control and digital display of welding voltage, current and time. (4) Special torch with extending cables, large lfiting force, low heat and durable. (5) Inner circuit board is under waterproof, anticorrosion, dampproof and dustproof treatment. (6) Compensatory capabilities of power voltage. When the voltage decreases, this machine can automatically stabilize welding parameters, when the voltage is extremely low, the machine still can work normally(only the max welding current is a little lower), the welding strength is much higher than ordinary welding machine. This feature applies to: electricity shortage and multiple equipments operating simutaneously in construction sites such as projects powered by generators, shipbuilding, steel construction etc.

3. Semi automatic welding machine Standard accessories and their connecting illustration

4. Semi automatic welding machine Applications (1) Mother materials and welding effects Carbon steel, low alloy steel, copper etc. materials with arc weldability. Welding in the workpiece surface of oxide layer, oil slick, priming paint or electroplate. After welding, no deformation, no convex, downward position welding, vertical position welding, overhead position welding, all position welding. (2) Applicable welding projetcs Kiln, boiler, shipbuilding, power plant, chemical engineering, mechanical equipment, various pipeline, vessel, bucket, vehicle manufacturing etc. thickness ≥ 2mm, welding M4mm—M22mm pins, studs, pin bolts, special-shaped pins, corrugated pins, anchoring parts etc. similar studs and bolts.

5. Quality Assurance and Quality Control System, Production Workflow As professional manufacturer of stud welding machines, welding torches and accessories, we possess special quality assurance and quality control system, and advanced production lines and complete workflows including high-quality raw materials purchasing, assembling, testing, packaging and delivery etc.

6. Semi automatic welding machine Operation (1) Locate the welder in a reliable, clear and safe site; (2) Connect the earth cable, lengthening cable, torch, chuck, grip, ferrule and stud; (3) Open power suply to observe digital welding voltage, current and time meters; (4) Adjust welding voltage, time and current, lifting height, extending length, chuck, grip, ferrule and stud (5) Trial welding to test whether all the parameters are correctly adjusted or not. If not, reset your welding parameters. (6) Begin to weld studs in your sites

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Packaging Details:

1. Outer package: sturdy plywood cases accessible to pallets

2. Inner package: welding machines covered by bubble covers and inside fixed by battens with nails; matched welding guns and other accessories packed by corrugated cartons.

3. Packaging Size

(1) Plywood cases: 1020mm*640mm*1100mm;

(2) DA-1200i: 880mm*368mm*560mm

(3) Accessories: 550mm*550mm*280mm

4. Container loading: 38 sets for 20GP, and 80 sets for 40GP

5. Delivery Details: 5 days for stock, 20 days for new

|

|

|

Specifications Solid stud welding machine 1.Low price, CE 2.Quick delivery 3.Fast welding,strong strength,low heat,less pollution

|

Leave your suggestion and opinion to the product (Please fill out the information below.* indicates a required field.)

| Product Name: | |

| Your E-Mail: | * |

| Content: | * |

| Security Code: |

|