Home > Products > WELDING STUDS... > SD-Shear Connector...

CONTACT US

- Tel: 86-510-85589569

- Email: info@solidstudwelding.com

- Fax:86-510-85589565

- Address: Taihu West Rd No.2168, Binhu District, Wuxi, Jiangsu province, CHINA.

SD-Shear Connector

- Introduction

- The models

- Advantage

- Inquire

Place of Origin:China (Mainland)

· Brand Name: SOLID

· Standard: ISO 13918, AWS D1.1, BS 5400

· Model Number: 10, 13, 16, 19,22, 24, 25

· Length:40mm-300mm

· Surface Treatment: Polish,phosphating,Nature

· Ferrule type: UF type

· Application: Steel structure,bridge,building,airport,tower,pipeline,road,railway

· Certificate: CE,ISO 9001,FPC BC1,SGS,BV,UKTC

· Tensile strength: >=450Mpa,>=495Mpa

· Yield strength: >=350Mpa,>=385Mpa

· Elongation: >=15%,>=20%,

· Technology: Drawn arc stud welding with ceramic ferrule

· Plates: embedded plates, frames, angles, strip plates and connections

· Materials: Low Carbon Mild Steel and Stainless Steel

· Welding options: general downward welding or welding through metal deck

Specifications

1. Applicable Scope of bolt and nut

(1) Nominal diameters: Φ10-25mm cheese head perfobond shear connector for composite constructions with ceramic ferrules for arc stud welding.

(2) Shear connectors are typically used in composite steel construction for holding concrete slabs to steel members to resist shear forces and increase shear loading capacity in steel buildings, bridges, columns caissons, containment liners, etc. They also act as embedment anchors on miscellaneous embedded plates, frames, angles, strip plates, attachments and connections.

2. Normative references

ISO 13918, AWS D1.1, BS 5400

3. Dimensions

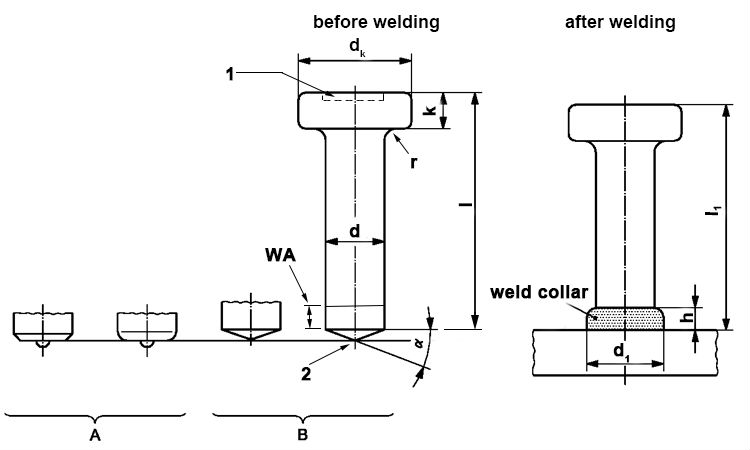

Symbols and abbreviated terms

d = nominal diameter

d1 = diameter of the weld collar

dk = head diameter of perfobond shear connector for composite construction

k = height of the head on perfobond shear connector for composite construction

h = height of the weld collar

l = overall length of the perfobond shear connector for composite construction (excluding aluminium ball or welding tip)

l = l1+WA

l1 = nominal length of the stud

WA = length of fluxing

A = shape A of tip

B = shape B of tip

1 = optional groove at manufacturer 's discretion

2 = optional arc welding tip at manufacturer's discretion

α = face angle

|

dimensions of bolt and nut (mm) |

|||||||

|

d |

d |

10 |

13 |

16 |

19 |

22 |

25 |

|

min |

9.64 |

12.57 |

15.57 |

18.48 |

21.48 |

24.48 |

|

|

max |

10 |

13 |

16 |

19 |

22 |

25 |

|

|

dk |

max |

18.35 |

22.42 |

29.42 |

32.5 |

35.5 |

40.5 |

|

min |

17.65 |

21.58 |

28.58 |

31.5 |

34.5 |

39.5 |

|

|

d1(1) |

13 |

17 |

21 |

23 |

29 |

31 |

|

|

h(1) |

2.5 |

3 |

4.5 |

6 |

6 |

7 |

|

|

k |

max |

7.45 |

8.45 |

8.45 |

10.45 |

10.45 |

12.55 |

|

min |

6.55 |

7.55 |

7.55 |

9.55 |

9.55 |

11.45 |

|

|

r |

min |

2 |

2 |

2 |

2 |

3 |

3 |

|

WA |

4 |

5 |

5 |

6 |

6 |

6 |

|

|

l1 (2) |

(3)mass of bolt and nut (SD) in kilograms per 1000 pieces (specific weight = 7,85 g/cm3) |

||||||

|

40 |

37 |

62 |

|

|

|

|

|

|

50 |

43 |

73 |

116 |

|

|

|

|

|

60 |

49 |

83 |

131 |

188 |

|

|

|

|

80 |

61 |

104 |

163 |

232 |

302 |

404 |

|

|

100 |

74 |

125 |

195 |

277 |

362 |

481 |

|

|

120 |

86 |

146 |

226 |

321 |

422 |

558 |

|

|

150 |

105 |

177 |

274 |

388 |

511 |

673 |

|

|

180 |

123 |

208 |

321 |

455 |

601 |

789 |

|

|

200 |

|

229 |

352 |

499 |

660 |

866 |

|

|

220 |

|

|

384 |

544 |

720 |

943 |

|

|

250 |

|

|

431 |

611 |

810 |

1050 |

|

|

300 |

|

|

|

722 |

959 |

1251 |

|

|

(1) d1 and h is the guide value. For special conditions, e.g. through-deck stud welding, they will be different. (2) l1 is the design value. For special conditions, e.g. through-deck stud welding, l1 will be shorter. (3) Due to the tolerances, the values of mass are only approximate. |

|||||||

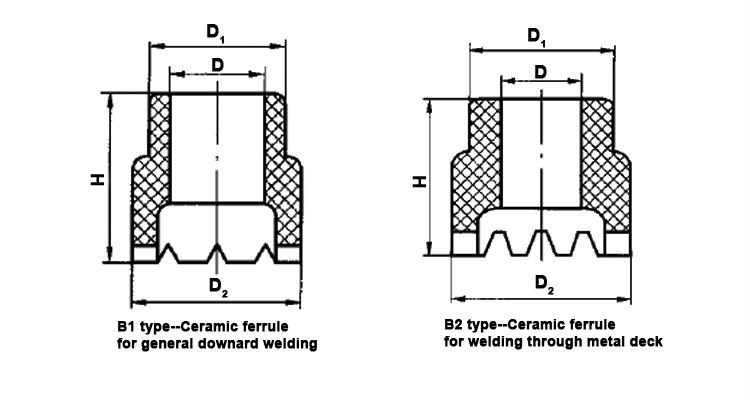

4. Ceramic ferrules for bolt and nut (UF)

|

dimensions of B1 type ceramic ferrules for bolt and nut (UF) (mm) |

|||||

|

diameter of perfobond shear connector for composite constructions d |

D |

D1 |

D2 |

H |

|

|

min |

max |

||||

|

10 |

10.3 |

10.8 |

14 |

18 |

11 |

|

13 |

13.4 |

13.9 |

18 |

23 |

12 |

|

16 |

16.5 |

17 |

23.5 |

27 |

17 |

|

19 |

19.5 |

20 |

27 |

31.5 |

18 |

|

22 |

23 |

23.5 |

30 |

36.5 |

18.5 |

|

25 |

26 |

26.5 |

38 |

41.5 |

22 |

|

Key 1. B1 type ceramic ferrules are mainly used for general downward welding as well as welding M13mm and M16mm perfobond shear connector for composite constructions through metal deck. 2. B2 type ceramic ferrules are only used for welding M19mm perfobond shear connector for composite constructions through metal deck. 3. The types of ceramic ferrules are at manufacturer's discretion. |

|||||

Packaging & Delivery

Packaging &Details:25 KGS per carton,48 cartons per pallet or 200 KGS per drum,6 drums per pallet.

Delivery Detail: 5days for stock,10-15 days for 1*20ft container.

Leave your suggestion and opinion to the product (Please fill out the information below.* indicates a required field.)

| Product Name: | |

| Your E-Mail: | * |

| Content: | * |

| Security Code: |

|